|

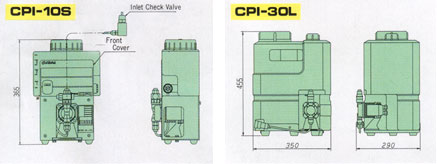

Chemical Feed PumpCPI Series

FLOW SHEET

|

SPECIFICATION

| Item | Unit | CPI_10S | CPI-30L |

| Installation | - | Wall Hanging Type/ Floor Type | Floor Type |

| Level Sensor | - | - | Option |

| ump Type | - | Magnetic Pulse Type | |

| Pump Control Method | - | Manual, Outernal Pulse | |

| Max. Outlet Capacity | cc/min | (*1)10 | (*1)30 |

| Max. Outlet Pressure | kg/cm² | 12 | 12 |

| Tank Capacity | ℓ | 3.5 (Cartridge Type) | 30 |

| Power Supply | v | (*1)100/200 (Single) | (*1) 200 (Single) |

| Dimensions (WxDxH) | mm | 230x175x365 | 350x290x455 |

| Net Weight (Dry) | kg | 3.5 | 6 |

|

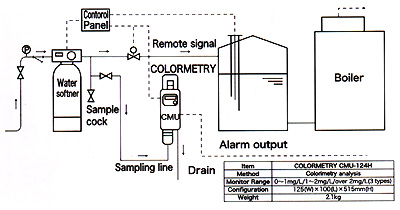

ColormetryCMU-124H Automatic monitoring system to detect the slightest water hardness leakage What is COLORMETRY (for Hardness) ? What hardness is considered to be the most common factor in damaging a boiler. The hardness level (ionic concentration) of water inflow to a boiler has been checked manually by using chemical reagents as an indicators. The manual measurement of these conventional methods comprises such problems as; time consumption; personal error or deviation; andlack of continuity in monitoring hardness leakage. COLORMETRY solves all these problems by offering an automatic monitoring system for sample water collection, chemical reagent injection, mixing and evaluation. |

SPECIAL FEATURES

1. Automatic monitoring system for hardness leakage

2. Detect the slightest hardness leakage

3. Easy to read digital screen

4. Alarm buzzer for information function

5. Momory function for recording hardness leakage incidents

6. One-Touch Cartridge Replacement

7. Compact Design

INSTALLATION FLOW EXAMPLE

SPECIFICATION

| ITEM | COLORMETRY CMU-124H | |

| Method | Colorimetry analysis | |

| Monitor Range | 0~1mg/L/1~2mg/L/over 2mg/L (3 types) | |

| Alarm Set Point | Over 1mg/L/over 2mg/L (choose one) | |

| External Alarm Output | Alarm output capacity at contact C: AC 24V 1A, Dry Contact | |

| Operation Output | Open collector output capacity: Dc 24V 70mA | |

| Raw Water Pressure | 0.05~0.5Mpa (0.5~5kg/cm2) | |

| Water Temperature | 5~40C | |

| Operation Temperature | 5~50C | |

| Humidity | 20~90%RH (no condensation, no freezing) | |

| Power | AC24V 50/60Hz | |

| Power Consumption | 20W | |

| Cartridge Replacement | Every 4 months (Note 1) | |

| Connector Size | Inlet | 6(diameter)tube (Note 2) |

| Outlet | 8(diameter)tube (Note 2) | |

| Installation | Indoor wall mount (Note 3) | |

| Configuration | 125(W)X100(L)X515mm(H) | |

| Weight | 2.1kg | |

|

BOILERMATE IS, IH SeriesCHEMICAL IS-101,102 BOILERMATE IS” series which had been developed as natural film type boiler compound is to be released instead of “BOILERMATE SX” series. “BOILERMATE IS” series is a natural film type boiler compound that is more environment friendly and had been developed with quite a new concept, which transforms feed water itself into the suitable quality for a boiler use by forming a film over tubes with silica innately contained in water. |

CHARACTERISTICS

USAGE

Put the undiluted solution into a chemical feed tank, and then a chemical feed pump doses automatically

the “BOILERMATE IS” with the boiler.

|

|

|

94, Jalan 24/2, Taman Megah,

47301 Petaling Jaya,

Selangor D.E. MALAYSIA

No. 3, Jalan Sungai Batu 8/KU6,

Taman Perindustrian Klang Utama,

42100 Klang,

Selangor D.E. MALAYSIA

+603-7804 5555 (Office)

+6019-388 5026

/ WhatsApp

+603-7804 0555 (Fax)

inmech@inmech.com