|

|

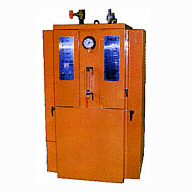

Electric Steam Boiler

Main Features

- Capacity. Extended to 480 kilowatts (48 HP).

- Electric element. Side entry individually flanged and bolted to provide quick and simple replacement at minimum cost.

- Fully package. With feed water pump mounted within boiler cabinet, all integrally piped and wired, pretested ready for connection to services.

- Restyled cabinets. With hinged panels to provide ready access to all working components.

- Working pressures to 725kPa (105 P.S.I.G). Higher pressures available.

- Approved in all states of Australia.

|

|

|

Advantages

- Fully automatic

- Fast steam raising

- Compactly packaged and self contained, no plant room required 99% thermal efficiency

- Low capital & low installation costs

- Low operating cost on process heating tariff

- No boiler attendant required (state regulations may limit maximum capacity)

- Simple installation requires only connection of water and electricity

- No flue-no fire-no risk of explosion-no fumes or smell

- No oil storage tank-no oil deliveries

- Clean equipment and work area

- Can be installed adjacent to steam appliance in workspace

- Negligible heat generated to surrounding area

- Quiet and reliable operation-low maintenance cost

- Fast response to changing load

- Versatility in operating hours

- Simple to operate and maintain-no sophisticated burner / ignition / draft controls - no fire brick maintenance

- Corrosion resistant, no heat transfer surfaces

- Low heating element replacement cost

- All spare parts available ex stock

- Fully qualified after sales services

- Comprehensive operating and maintenance instructions, wiring and piping diagrams accompany each boiler

|

|

|

Applications

- Hospital sterilizers

- Autoclaves

- Laundries

- Dry cleaners

- Industrial process heating

- Food processing

- Steam jacketted pans for heating food, pharmaceutical, cosmetic & chemical products, etc.

- Humidification to air conditioning systems for humidity control, eg. Computer & punch card rooms textile laboratories textile & tobacco rooms research centres operating theatres, etc.

- Steam injection to bakery & pastry ovens, dairies, tool steel, cable making, etc.

- University research, teaching & development applications

- Kitchen equipment

- Steam cleaning

- Washing & drying

- Hot water storage heaters

- Horticulture soil sterilising

- Stills

- Honeycomb de-capping

- Timber moulding

- Steam rooms

- Tyre retreading equipment

- Clothes pressing & ironing machinery

- After hours steam raising plant

- Supplement steam raising plant for applications remote from main steam plant.

|